Rumored Buzz on Machine Nozzles

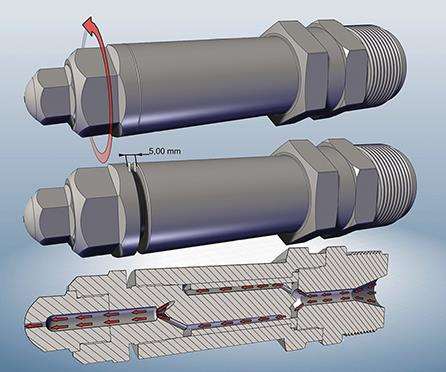

The layout may additionally consist of a way of diverting any thaw that locates its means along the shut-off needle far from the springtime. Furthermore, if the barrel is left unattended with heats up on for a prolonged amount of time, the springtime needle shut-off layout has the benefit of an integrated safety and security attribute, in instance the device nozzle and/or injection barrel start constructing stress.

If the the valve is then opened up with the thaw at the raised stress, the thaw may shoot out of the machine nozzle uncontrollably, developing a potentially hazardous situation. Even worse, if the shutoff is closed quickly enough to release the pressure, the pressure may develop to a disastrous degree, again causing a potentially dangerous circumstance with little or no caution.

This is one more instance of how the layout and engineering of equipment nozzles has boosted substantially over the last few years. The issues of excessive pressure decrease in nozzle filters; excessive shear and/or tension in mixing nozzles; and the high price and also complicated set-up and operation of shut-off nozzles have been resolved through efficient and efficient design as well as engineering.

REGARDING THE AUTHOR Chuck Azzopardi is head of state of HMM Solutions Inc., Salida, Colo., which uses sales and also assistance for equipment nozzles and also mold and mildew components from Müller Mekaniska AB of Sweden. Before creating HMM, Azzopardi was project/staff designer at Plastic Engineering & Technical Provider (P.E.T.S.) for seven years; elderly shot molding expert at BASF for eight years, and also an item manager and also international manager at DME Firm for nine years.

If you were getting an injection molding maker two decades back, you had to decide in between a toggle or completely hydraulic clamp which was practically it. Put in the time to do the viscosity contour on new molds. You will find out more in that hour than lots of learn in years regarding the procedure for this device.

Fascination About Machine Nozzles

We are gladly readily available for you on Monday to Thursday from 7:30 a.m. to 5:00 p.m. as well as Friday from 7:30 a.m. to 4:00 p.m.

Our most prominent package. This supplies all the replenishment components you'll require over an extended time including extra slats, mixing tubes, orifices, garnet feed line, blending tube retainer nut, nozzle body o-ring, water filter, dash guard and also last opportunity filters plus the drainpipe water filter container as well as water spray nozzle.

Greater precision, simpler, better: Our Grindaix nozzles are not brochure goods, but independently adjusted coolant nozzles precisely customized to the specific device. We offer nozzles for all manufacturing processes. machine nozzles. With the Grindaix nozzle, the lubricoolant is supplied to the machining website in a targeted way-- constantly metered specifically as well as based on needs! The coolant departures the nozzle at high rate, to ensure that it reaches the machining website with optimal performance.

Furthermore, the cycle time as well as the performance of your production can be maximized. We establish tailored nozzle solutions-- even for your individual application! Our engineering solutions are currently included in the rate and are not invoiced separately. We adjust lubricoolant supply systems to your requirements-- both relative to the application as well as the procedure.

Every Grindaix nozzle has a specific characteristic curve, which permits us to readjust all the specifications exactly to your procedure. Not just brand-new equipments may be fitted with Grindaix nozzles. Your existing machines can additionally be retrofitted as well as maximized by the Grindaix group. It is even worth converting older makers, as a return on investment is mainly attained within a short time and also at the current after year.

The Best Guide To Machine Nozzles

Besides needle nozzles in common designs, which we carry supply for you, we can also provide the design and production of a Grindaix nozzle as an unique design in the majority of cases. Our specialists look onward to getting your inquiry!High lubricoolant exit speed Targeted supply to the machining site All profile-adapted nozzle types may besupplied for all production processes Optimal lubricoolant usage with respectto pressure, flow price, exit speed Reduction in filtration volume Decrease in device wear Boost in performance Avoidance of waste Enhancement of your Carbon Monoxide 2 equilibrium.

Clean-in-place (CIP) is a design principle frequently utilized in markets that require constant inner cleansing of their procedure tools and depend on a high level of cleanability to keep their systems in order to meet stringent hygienic requirements. This includes yet is not restricted to drugs, fine chemicals, processed food, drink and also cosmetics.

Clean-in-Place-- CIP signifies the cleansing of all indoor surface areas consisting of vessels, pipelines, linked fittings, and also other process devices all without disassembly. machine nozzles. Sterilization-in-Place-- SIP needs the highest level of cleanliness, in which all microbes and also germs are removed and also the vessel is thought about totally disinfected. This includes heat right into the cleansing (commonly equipment is sterilized if it can be verified that every area of the machine has actually reached a temperature level of 250 ° F( 121 ° C) which has actually been maintained for at the very least 20 minutes).

It optimizes time (reduced cleansing cycles, no labor to dismantle components or manually clean), enhances the health of the operation (which in turn improves the item quality), as well as offers an environmental advantage of better making use of water, cleaning agent as well as other sources required in the cleaning procedure. In summary, CIP boosts the total performance of the procedure.

Filter/Dryers are different from glass-lined vessels, and also for that reason the cleaning system they use will certainly require to be various as well. Several of the elements that enter consideration when making a CIP system include: Intricacy of tools-- geometry, setup, product of building, piping alignment, nozzle and also discharge valve areas, and so on (machine nozzles).

The smart Trick of Machine Nozzles That Nobody is Discussing

Option of a detergent/cleaning representative-- avoidance of potential chemical response with item deposit, option type (acidic or alkaline, anionic, non-ionic, cationic, or amphoteric), concentration, contact time, temperature, and so on. Cleaning devices hardware-- spray balls, spray rings, positioning hardware (stationery or revolving), quantity, installation location, hydrodynamic pressures, high/low pressure options.

reference Full Report More hints